MANUFACTURING

WE MANUFACTURE TRUST

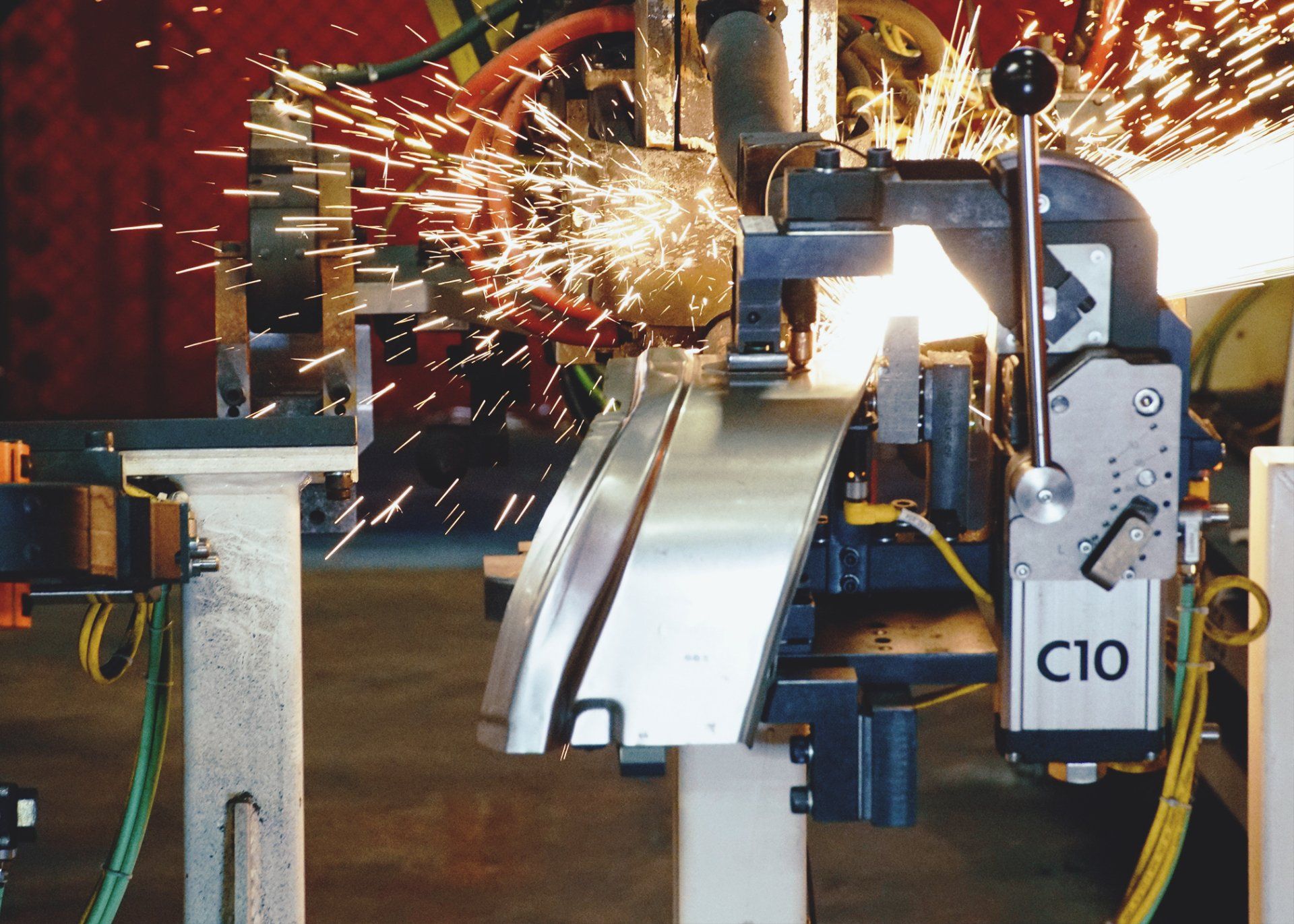

JOINING & WELDING

As customer demand for reduced vehicle weight has grown, Autokiniton has become a leader in the joining of dissimilar metals. Aluminum, hot-formed, and high-strength steel have become common, providing us with opportunities to increase the incredible value we bring to our customers. We use a wide range of joining technologies to manufacture assemblies. Our welding capabilities include gas metal arc welding, resistance spot welding, capacitive discharge welding, drawn arc welding, laser welding, and friction stir welding.

MIG WELDING

1,200+

MIG Welding robots (AND COUNTING...)

MIG welding is a welding process in which an electric arc forms between a consumable MIG wire electrode and the surface to be welled. The electric arc heats the metals, causing them to melt and join. Along with the wire electrode, a shielding gas feeds through the welding gun, which shields the process from atmospheric contamination.

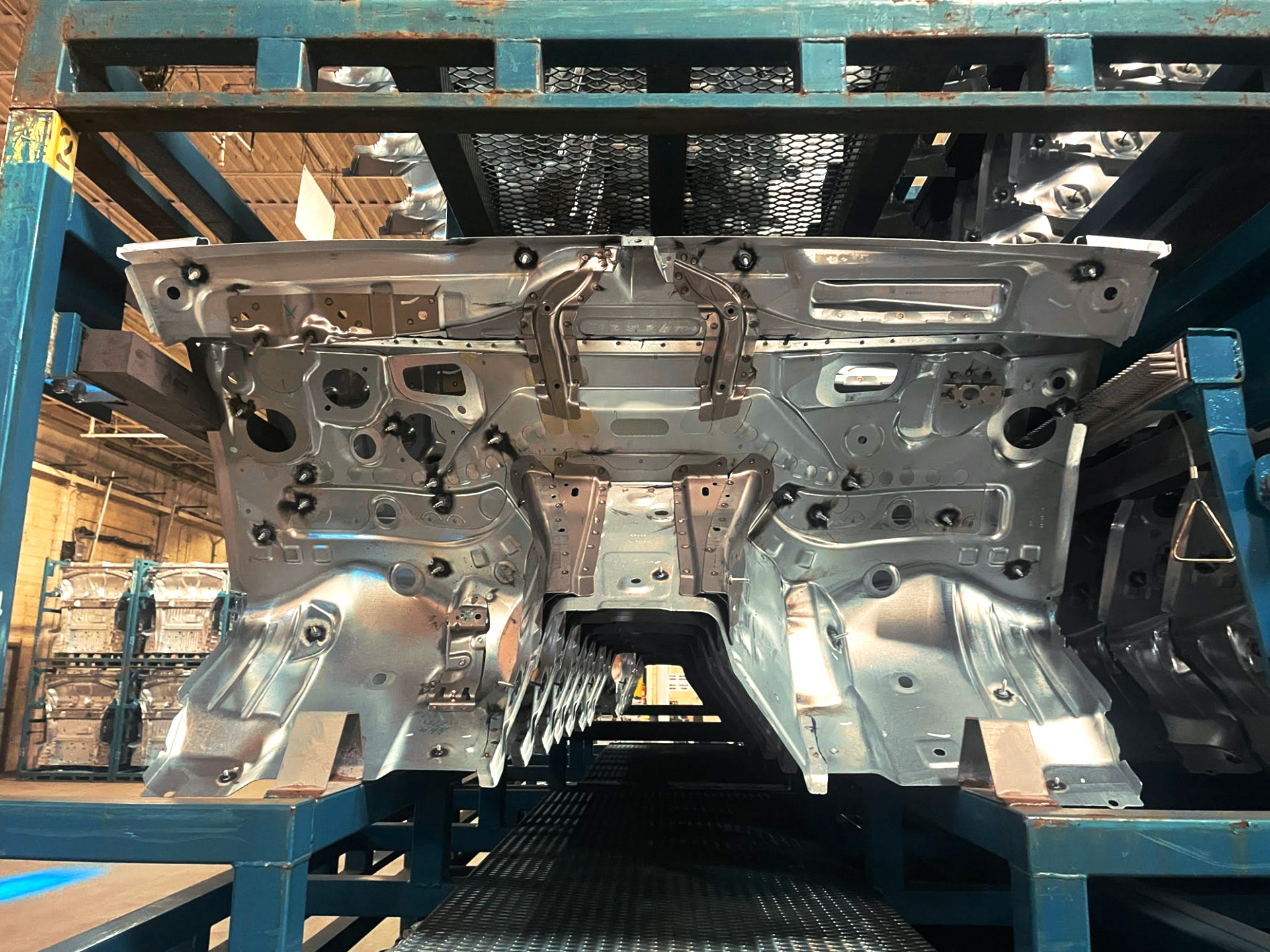

COMPLEX ASSEMBLIES & BODY IN WHITE

We refer to "body-in-white" as the manufacturing state in which the vehicle body sheet metal has been assembled but before the components and trim have been added.

COMPLEX ASSEMBLIES

FRONT & REAR FLOOR PAN

DOOR/PILLAR ASSEMBLIES

Complex assemblies are comprised of multiple components and sub-assemblies that are joined to form major portions of a vehicle's body structure. Autokiniton provides state-of-the-art lightweighting and structural benefits through complex assemblies. Examples of complex assemblies include front and rear floor-pan assemblies, as well as door/pillar assemblies.

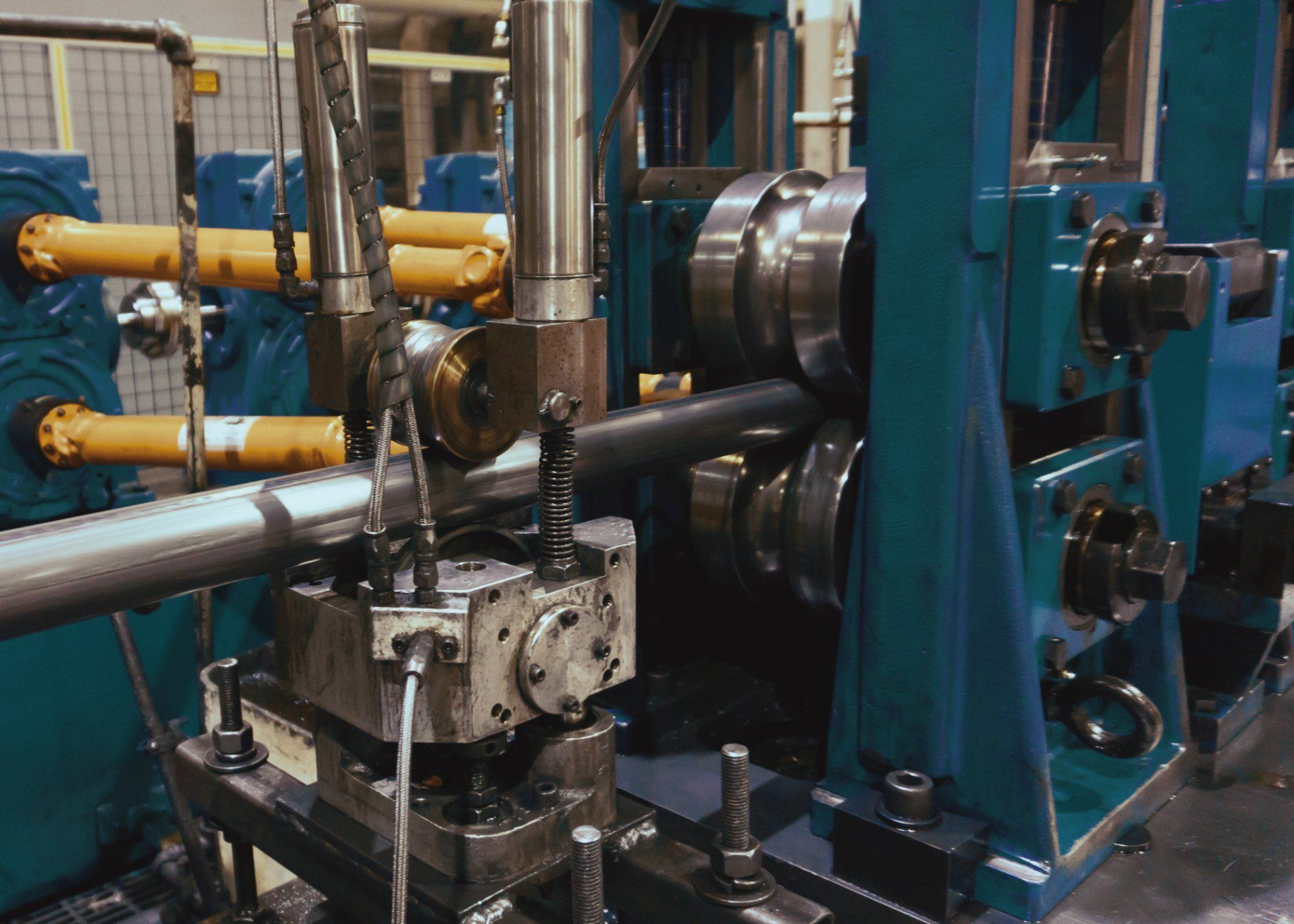

TUBE FORMING MILL

Autokiniton offers induction resistance welded tubing and fabrication. We manufacture a variety of round, square, and rectangular tubing shapes for the automotive, trailer, and recreational vehicle industries. Our comprehensive quality lab in Michigan performs crush & cone tests, metallurgical etching, tensile testing, and hardness testing.

TUBE & ROLL FORM

3 TUBE MILLS

2 ROLL FORM MILLS

Roll forming is a type of metal forming involving the continuous bending of a long strip of sheet metal (typically coiled steel) into a desired cross-section. The strip passes through sets of rolls mounted on consecutive stands, each set performing only an incremental part of the bend, until the desired cross-section (profile) is obtained. Roll forming is ideal for producing constant-profile parts with long lengths and in large quantities.

COLD STAMPING

Autokiniton produces parts using precision single-stage, progressive, tandem, and transfer presses, ranging in size from 100 to 4,500 tons.

We perform multiple functions to convert raw material into finished products, including stamping, roll forming, and roller hemming.

While the majority of our cold forming is done on steel, an increasing number of our customers use aluminum to reduce vehicle weight and optimize vehicle fuel efficiency. Autokiniton has made a strong investment in servo presses that are suited for both aluminum and steel.

TANDEM PRESSES

214 Presses

UP TO 3,000 Tons

The tandem press line refers to any line of individual presses, which may be used in conjunction with a set of dies that completes the processing of a part or parts from blank to finished stamping.

This is as opposed to individual presses that are used separately to complete only limited portions of the production of a part. Commonly with tandem lines, automation will be placed in between the separate presses to handle the movement of the parts from operation to operation.

TRANSFER PRESSES

40 Presses

UP TO 3,000 Tons

Sheet metal forming in medium-high volume production environments is often completed through the use of a transfer press operating a number of dies as a complete system. Each die in the system is responsible for adding more shape to the part until the metal work piece attains its final shape. With each closing of the press the entire system of tools will close, each performing its designed work to the sheet metal. Upon opening, the built in transfer mechanism moves the workpiece from one operation to the next in the sequence.

PROGRESSIVE PRESSES

105 Presses

UP TO 1600 Tons

Progressive stamping is a metalworking method that can encompass punching, coining, bending and several other ways of modifying metal raw material, combined with an automatic feeding system.

The feeding system pushes a strip of metal (as it unrolls from a coil) through all of the stations of a progressive stamping die. Each station performs one or more operations until a finished part is produced and sent down the conveyor for delivery to the customer.

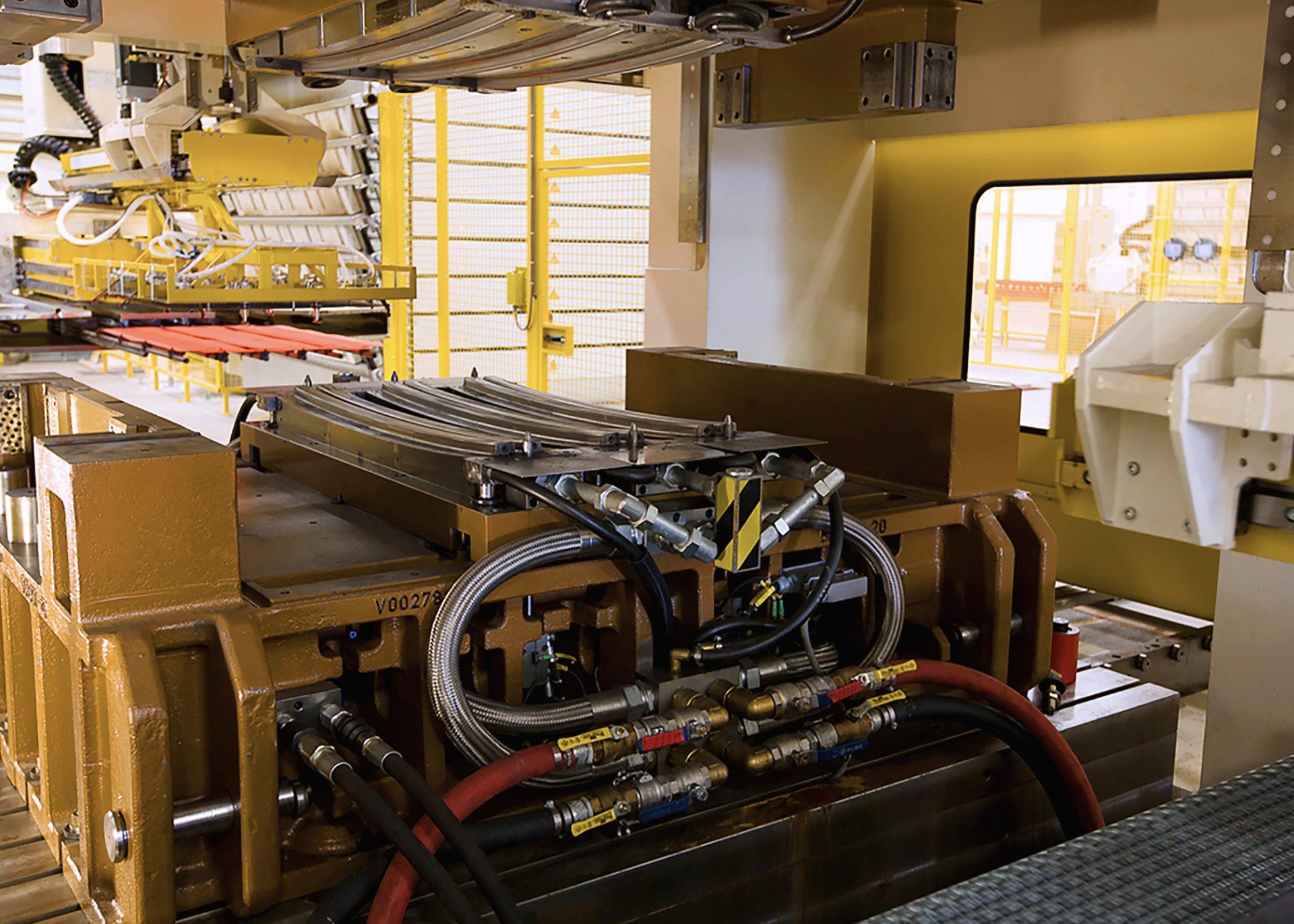

HOT STAMPING

Autokiniton’s hot-stamping technology provides customers with ultra-high-strength steels (UHSS) for automotive body structures.

Demand for UHSS is increasing to meet regulatory requirements for fuel economy through vehicle weight reduction while

maintaining vehicle safety.

The hot stamping process involves heating sheet steel in a furnace, then stamping it while hot in a press with water-cooled dies.

The result:

stamped parts made of UHSS that have metallurgical characteristics and mechanical properties that allow for significant vehicle

weight reduction and higher levels of strength.

HOT STAMPING

8 HOT STAMP LINES

23 LASER UNITS

In a hot stamping process, press-hardenable boron, coated steel is heated in a furnace to an austenite temperature in excess of 900°C.

The material is then rapidly transferred to a press where a water-cooled hot stamp die flash cools the material during forming. This quench cooling causes a change in the material grain, resulting in a material phase transformation from austenite to martensite. This process converts low-tensile-strength metal to a very high-strength steel.

LASER CUTTING

Autokiniton has some of the most advanced laser systems in the world.

LASER MACHINES

40 LASERS

1,000 LB Capacity

Laser cutting is a technology that uses amplified light to slice materials. Lasercutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the material or the laser beam in precise movements.

A commercial laser for cutting materials uses a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish.

END TO END

PROCESS & PROGRAM

Autokiniton’s manufacturing operations consist of extensive stamping and welding operations, system and modular assembly operations, and coating operations. Our commitment to vertical integration extends to the state-of-the-art process technologies and program-management services we provide.

Our program management follows the advanced quality project plan, and we engage with our customers from the early stages of the program definition. Our work continues through product and process design, development, and validation and we provide feedback, assessments, and corrective action plans to ensure operational stability after a product launch.

Our dedication to teamwork, speed, simplification, performance, and empowering our associates has made us a trusted supplier to the top manufacturers.