IN HOUSE ADVANCED

ENGINEERING & INTEGRATION

Our commitment to vertical integration means that our engineering expertise feeds into our manufacturing, material-management, and logistics services. We draw upon our advanced capabilities to design and manufacture superb products.

SAFETY & QUALITY

BEGIN WITH STRUCTURE

AXIS

OUR IN HOUSE SOLUTION

Axis builds and integrates tools & dies along with full assembly capabilities. From concept to completion, we understand what it takes to create a part - and then design the assembly equipment and processes to produce that part.

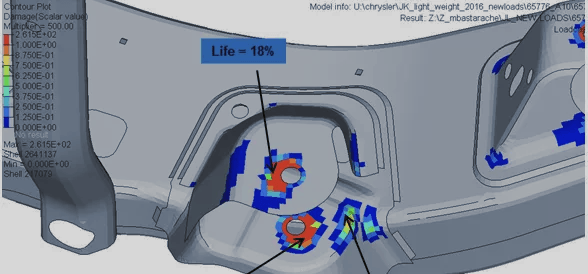

PRECISION BODY IN WHITE ENGINEERING

Autokiniton also engineers lower vehicle frames and chassis structures that create the “skeleton” of a vehicle. Our solutions contribute to overall performance, particularly in the areas of noise, vibration and harshness, handling, and impact management.